Optiguard™ AROL Anti-Reflection Optical Laminate

Tax included

92 in stock

AROL Anti Reflection Film

Optiguard™ AROL (Anti Reflection Optical Laminate)

Optiguard™ AROL has been specially developed by Panel Graphic to enable more products to benefit from an affordable AR coating solution. Exceptional light transmission and anti-reflective properties combined with excellent durability makes Optiguard™ AROL the ideal solution for a broad range of applications.

- NO minimum order quantities

- ANY custom sheet size – minimal waste

- ANY material

- ANY thickness

- ALL from stock ensuring short lead times

Anti Reflection Optical Lamination coating will dramatically reduce scratching when applied to acrylic or polycarbonate sheet giving surface hardness approaching that of glass together with superior resistance to chemical attack.

It is suitable for internal and external use but it is recommended that UV stable substrates be used when exposed in direct sunlight.

AROL Features

- Excellent transmission and overall visual performance achieved by utilising optically clear adhesive

- The hard coat layer gives high levels of abrasion resistance with the added benefit of fingerprint

resistance – also known as AFP or ETC - Excellent durability. Environmental exposure testing to ISO 16474-3 method A, including exposure

to 5% salt solution - Suitable for application via pressure lamination process to a wide range of substrates including

PMMA, Polycarbonate and Glass

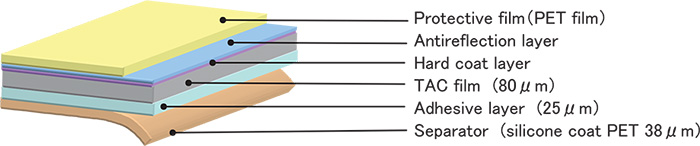

AROL Structure

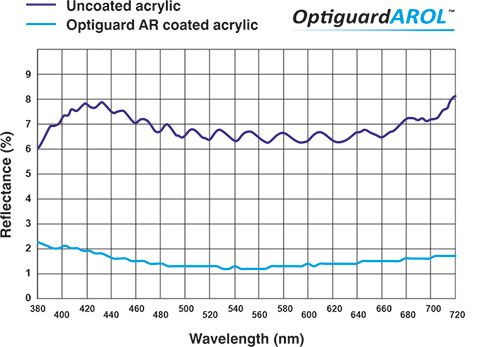

AROL Optical Properties

| Evaluation Item | Measured Value |

|---|---|

| Total Light Transmittance (%)1 | 95.9 |

| Haze (%)1 | 0.4 |

| Reflectance (%)2 | 1.2 |

1Measured with film laminated to glass

2The regular reflectance of 5° is measured by spectrophotometer (550nm)

(Adhesive film adhered to glass, back painted black)

AROL Physical Properties

Adhesive Surface

| Coating Thickness (µm) | Micrometer | 25 | |

| Adhesive strength for glass (N/25mm)3 | For Glass | RT x 30min | 15.0 |

| 23°C x 65% x 24h | 18.2 | ||

| 65°C x 95% x 24h | 23.5 | ||

3Peeling angle: 180°. Peeling speed: 300mm/min

Anti-Reflection Surface

| Steel Wool Rubbing | No Scratches | # 000 Steel Wool: 250g/cm2 x 10 (Back and forth) |

| Surface Hardness4 | 4H | JIS k5400 (Value of the base film only) |

| Coating Layer Density | 100/100 | Cross-Cut Test |

| Contact Angle (°) | 105 | Water Contact Angle |

| Fingerprint Removing Property | ⊚ | – |

4JIS k5400 compliant

Chemical Resistance

| After Dripping | ||||

|---|---|---|---|---|

| Chemical List | Concentration | Immediately | 1 minute | 5 minute |

| Ammonia aqueous solution | 2% | Ο | Ο | – |

| 3% | Ο | – | Ο | |

| Gasoline (Lead-free) | 100% | Ο | Ο | – |

| Detergent | 10% | Ο | Ο | – |

| Weak alkaline detergent | 10% | Ο | Ο | – |

| Saline | 10% | Ο | Ο | – |

| 19% | Ο | – | Ο | |

| Acetic acid | 10% | Ο | Ο | – |

| Isopropyl alcohol | 50% | Ο | Ο | – |

| Acetone | 100% | Ο | – | Ο |

| Ethanol | 100% | Ο | – | Ο |

| Methanol | 100% | Ο | – | Ο |

| Acetic acid aqueous solution | 2% | Ο | – | Ο |

Ο: No Change

×: Minor Change

Evaluation Method

- Drop each chemical on the AR film surface so that it has a diameter of 10mm

- After the stated time has passed, wipe off the chemicals with gauze

- Visually evaluate any changes in the AR film surface

Bonding Adhesive

Film type: AROL / ARTAC40 / ARTAC60Z / AGLR80-6K / AGLRPET80

| OCA Thickness | 25 | ||

|---|---|---|---|

| High Temperature | 95°C | 500h | OK |

| 1000h | OK | ||

| High Temperature | 60°C/90% | 500h | OK |

| High Humidity | 1000h | OK | |

| Low Temperature | -40°C | 500h | OK |

| 1000h | OK | ||

| Thermal Shock | 95°C⇔-40°C | 500h | OK |

| 30 min | 1000h | OK | |

Test sample: Leave the samples laminated on the soda glass at ambient room temperature for one day, then test.

OK = No change of appearance (No film lifting, peeling, bubbling or yellowing)

Film Comparisons

| Item | Product | Measuring Method | ||||

|---|---|---|---|---|---|---|

| AROL | ARTAC40 | ARTAC60Z | AGLR80-6K | AGLRPET80 | ||

| Thickness Base Film | 80 µm TAC | 40 µm TAC | 60 µm TAC | 80 µm TAC | 80 µm SRF-PET | – |

| Total Light Transmittance (%) | 95.9 | 96.5 | 95.9 | 93.9 | 95.3 | JIS K 7105 |

| Haze (%) | 0.4 | 0.4 | 0.5 | 5.8 | 7.5 | JIS K 7105 |

| Reflection (%) | 1.2 | 0.4 | 0.19 | 1.2 | 0.94 | 5° Reflection (550nm) |

| Hydrophobic Properties | Ο | – | Ο | Ο | Ο | – |

| Adhesive Strength (N/25mm) | ≥ 10 | ≥ 10 | ≥ 10 | ≥ 10 | ≥ 10 | To Glass (After 24 hours) |

| Pencil Hardness | 4H | 4H | 4H | 5H | 4H | AR Film Itself (Without OCA) |

| Application | Tablet Automotive Laptop PC |

Tablet Automotive |

TV VR Device Interior Material |

Automotive | Automotive | – |

Ο: Yes

Δ: No